Setting blind rivet nuts with traction force adjustment

This means that the tool will stop pulling the blind rivet nut when a pre-adjusted traction force threshold is reached. No re-adjustment is needed when setting blind rivet nuts into different material thicknesses or when using blind rivet nuts with different shaft lengths. Traction force control prevents damage of the material which cannot be overstressed by a too high setting pressure and preserves the integrity of the blind rivet nut thread. As a bonus, it also extends the life duration of the threaded mandrels. The desired traction force threshold can be very simply adjusted with an allen wrench once the stroke adjustment has been set to the maximum.

Setting blind rivet nuts with constant stroke adjustment

This means that the tool will pull the blind rivet nut with its maximum force and stop immediately when the pre-adjusted stroke has been covered, nut for nut, safely and reliably. The stroke adjustment is easily and clearly performed using a millimetre scale on the tool adjustment thumb wheel, without the need for any tool, after having adjusted the pulling force to its maximum. The millimetre adjustment scale exactly reflects the effective stroke of the threaded mandrel, so that maladjustment is nearly impossible. Moreover it is safely locked to prevent any drift. The protruding length of the threaded mandrel can be adjusted manually.

Easy operation through automatic drill-on function

The drill-on process will automatically start when a blind rivet nut is lightly pressed onto the mandrel tip. This avoids the cumbersome double action on twin triggers. Thereafter introduce the blind rivet nut into its setting hole, press the trigger and keep it depressed until the setting cycle is completely finished, nut drilled off and tool free. It couldn’t be easier!

Extremely fast working cycle

Great care has been taken to shorten every sequence of the setting cycle to its absolute minimum: Pulling sequence and subsequent automatic drill-off take place at breathtaking speed and require only a single action on the trigger.

Can be operated with DIN EN ISO 4762 allen screws instead of threaded mandrel.

Special adapters available as accessory for M4 to M8 threads allows the original threaded mandrels to be replaced by allen screws: a substantial cost saving without any quality or performance loss and higher endurance when far away from the spare parts source. Best results are obtained with 12.9 grade screws.

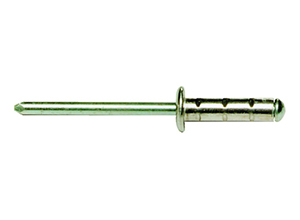

Sets blind rivet nuts from M3 to M12, also those with extended grip range.

The wide range of suitable thread sizes provides the FireFox® with a large variety of possible operation. The choice between stroke and traction force control also makes it suitable for industrial applications where several material thicknesses need to be covered, which would normally require the use of several tools. Moreover, its outstanding 10mm stroke is ideally suited to the new generation of large grip range blind rivet nuts, like the GESIPA PolyGrip® products.

Standard accessories:-

- 2 wrenches SW24/27

- 1 Allen screw driver SW4

- 1 Oil can with 100ml hydraulic oil

- 1 Oil refilling can

- Operation manual

- Threaded mandrel (please choose from M3, M4, M5, M6, M8, M10, M12 when ordering)

Available seperately:-

- Adapters for use of allen DIN EN ISO 4762 (12.9 quality) instead of threaded mandrels M4 to M8

- Adapters for setting of blind rivet nut studs M4 to M8

- Nosepieces and threaded mandrels with UNF/UNC threads

- Complete sets of nosepieces and threaded mandrels.

Reviews

There are no reviews yet.